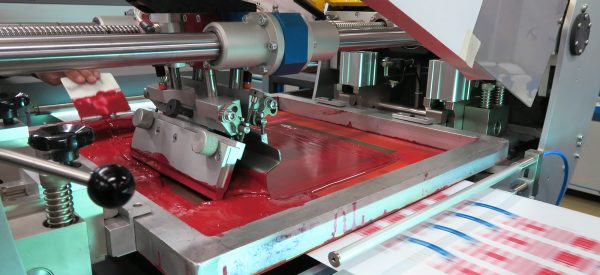

DIRECT SCREEN PRINTING

The screen printing method is an extremely durable printing technique used on clothing. It is often confused with the popular early “iron-on” methods that had limited durability and were suitable for single-use only. The screen printing process involves depositing ink onto the fabric, allowing for a seamless integration with the material (the texture of the fabric is still perceptible). This method ensures high color durability, resistance to washing and abrasion. It is commonly used for marking lightweight cotton garments such as T-shirts, polo shirts, as well as other textile products like promotional lanyards, bags, sacks, or hats.

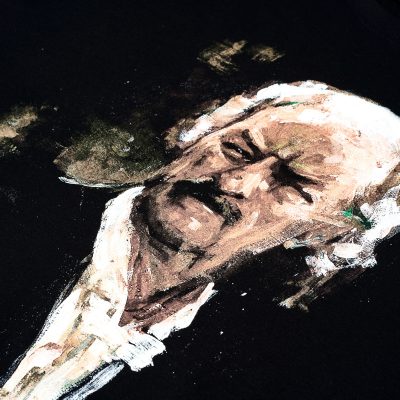

Some of our projects:

Why Direct Screen Printing?

1. Quotation

2. Design

3. Delivery

FAQ

Direct screen printing is primarily suitable for fabrics such as cotton, polyester, and fabric blends. It can also be used on some other materials, but it achieves the best results on textiles.

Yes, direct screen printing ensures durable and vivid prints on clothing. The ink is directly infused into the fabric, ensuring high-quality and long-lasting patterns.

Yes, direct screen printing allows for printing full-color graphics. Rich and vibrant colors can be achieved, making this technique ideal for multi-colored designs.

The minimum order quantity depends on the printing company, but direct screen printing is a flexible method that can be used for both small and larger quantities

Yes, direct screen printing is perfect for multi-color designs. Each color is individually applied to the fabric, enabling rich and intricate patterns.

Direct screen printing offers exceptional durability, excellent print quality, the ability to print full-color graphics, and high resistance to washing. It is also cost-effective for larger quantities, and the prints are fade-resistant, creating a long-lasting promotional effect on clothing.